INSTALLATION

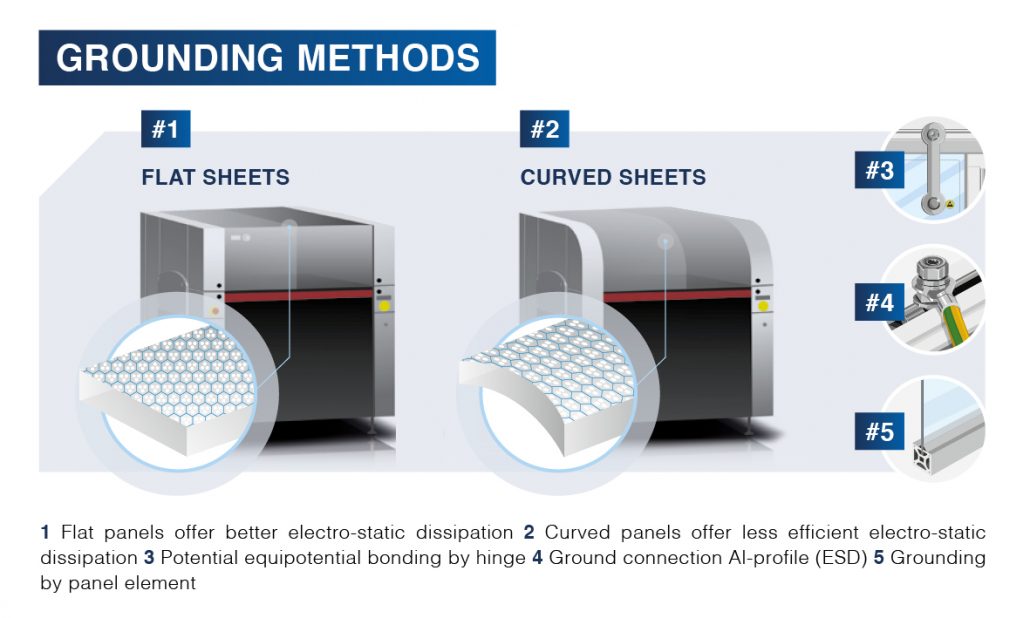

GROUNDING

In order to achieve optimum dissipation of electrostatic charges, ESLON®-DC ESD plastic sheets should be grounded on the upper side. The decay time while grounded is less than one second, the surface potential remains at a value between 0 and approx. 25 volts. Without grounding, the dissipation of static electricity may be delayed by several seconds.

A fixed contact point is sufficient for grounding.

Exemplary connections:

· screw connection with cable or grounding tape (with washer if necessary)

· mechanical contact with electrically conductive metal (e.g. profile frame)

· use of electrically conductive sealing compound or e.g. conductive silver paint

· metal clamp connection

CLEANING AND CARE

For cleaning ESLON®-DC ESD Standard plastic sheets, we recommend cleaning agents like isopropyl alcohol (IPA), alcohol-based cleaning liquids and water. Do not use cleaning agents based on organic solvents (e.g. acetone, ketone, benzene or toluene) or abrasive cleaning agents.

ESLON®-DC ESD Hard Coat plastic sheets can be cleaned on the surface with organic solvents.

SCRATCHES

After a while, in any production process, scratches may occur on ESLON®-DC ESD plastic sheets. Single scratches have no impact on the antistatic dissipation. A large number of scratches increases the surface resistance – however, the dissipative effect is lost if there are visibly more scratched areas than there are still transparent areas. If the material is heavily scratched due to polishing

machines, the performance of the antistatic coating can no longer be guaranteed!