ESLON®-DC ESD Polycarbonate – Characteristics

Flammability

International Standard: Underwriter’s Laboratories UL-94

EU respectively National Standard: DIN EN 60695-11, respectively VDE 471.

Testing for the evaluation of fire hazards is carried out with a vertical and a horizontal test flame. All available ESLON®-DC ESD PVC plates meet the globally accepted UL 94 Standard with the highest classification, i.e. V-0. ESLON®-DC ESD Polycarbonate meets this standard in the Hard Coat version from a thickness of 6mm on, or in the special versions of 3mm and 5mm. ESLON®-DC ESD PMMA complies with the requirements of the horizontal burn test, but does not meet the requirements of the vertical burn test.

Please find below an overview of the V-0 certified Polycarbonate materials to date:

Please find below a short explanation of the testing procedure and classification:

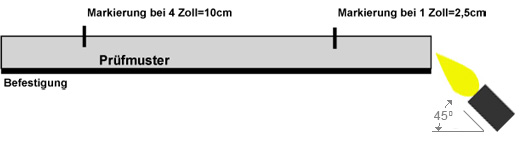

Procedure A Horizontal Burn (HB = horizontal burn)

The corner edge of a horizontally fixated test specimen is held into the open test flame at a 45° angle. The flame is applied over a period of 30 seconds, i.e. is terminated when the test flame has exceeded the 2.5 cm (1 inch) mark. In case the test specimen should continue to burn, the time it takes the flame to burn up to the 10 cm (4 inch) mark is recorded. In case the test specimen self-extinguishes before reaching the 10 cm mark, the burn-off and the length of the burn traces between the two markings is recorded. The test is conducted with three test specimen sets per plate thickness.

HB Classification carried out according to:

1.a) a specimen thickness of 3mm to 12.7mm. The burning rate of the test specimen shall be below 1.5 inches per minute

1.b) a sample thickness of under 3mm. The burning rate of the test specimen shall not exceed

3 inches per minute

2. The test specimen must not burn any further than to the 4-inch mark.

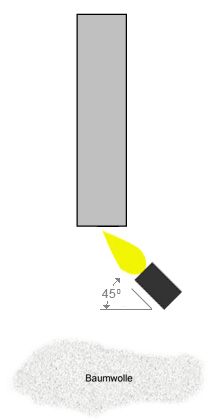

Procedure B Vertical Burn (V-0, V-1, V-2 = vertical burn)

| The test specimen is fixated in a vertical position and the flame is applied to its bottom edge corner for 10 seconds, afterwards removed until the test specimen stops burning. Subsequently, the flame is reapplied for an additional 10 seconds and then removed. Overall, two trials comprising of five test specimens each using various prior conditioning methods were inspected. |  |

Highest Classification: V-0

1. None of the test specimens may burn with flaming combustion for more than 10 seconds.

2. The total flaming combustion time may not exceed 50 seconds for each group of five test specimens.

3. The test specimens may not burn to the upper holding clamp with flaming or glowing combustion.

4. The test specimen must not emit any flaming particles which could ignite the cotton at the bottom of the test apparatus.

5. No test specimen may have glowing combustion for more than 30 seconds after the removal of the test flame.

Classification V-1

1. None of the test specimens may burn with flaming combustion for more than 30 seconds.

2. The total flaming combustion time may not exceed 250 seconds for each group of five test specimens.

3. The test specimens may not burn to the upper holding clamp with flaming or glowing combustion.

4. Test specimens must not emit any flaming particles which could ignite the cotton at the bottom of the test apparatus.

5. No test specimen may have glowing combustion for more than 60 seconds after the removal of the test flame.

Classification V-2

1. None of the test specimens may burn with flaming combustion for more than 30 seconds.

2. The total flaming combustion time may not exceed 250 seconds for each group of five test specimens.

3. The test specimens may not burn to the upper holding clamp with flaming or glowing combustion.

4. Test specimens may emit flaming particles which could ignite the cotton at the bottom of the test apparatus.

5. No test specimen may have glowing combustion for more than 60 seconds after the removal of the test flame.